Electric motors are ubiquitous in modern life, powering everything from household appliances to industrial machinery. These devices convert electrical energy into mechanical energy, providing motion and power for a wide range of applications. In this comprehensive guide, we delve into the workings of electric motors, exploring their history, principles, types, applications, and maintenance.

Understanding Electric Motors

Electric motors are electromechanical devices that convert electrical energy into mechanical energy through electromagnetic induction. They operate on the principle of Faraday’s law of electromagnetic induction, which states that a current-carrying conductor placed in a magnetic field experiences a force. This force creates rotational motion, allowing electric motors to drive various mechanical systems.

History of Electric Motors

The development of electric motors dates back to the early 19th century, with pioneers such as Michael Faraday and William Sturgeon laying the groundwork for modern motor technology. The invention of the electric motor revolutionized industry, transportation, and everyday life, enabling the widespread adoption of electric power for a variety of purposes. Over the years, electric motors have evolved significantly in terms of design, efficiency, and performance, driving progress and innovation across multiple industries.

Principles of Operation

Electric motors operate based on the interaction between magnetic fields and electric currents. When an electric current flows through a wire coil (armature) placed in a magnetic field, a force is exerted on the coil, causing it to rotate. This rotational motion is harnessed to drive mechanical loads such as fans, pumps, conveyor belts, and propulsion systems. The speed and torque of an electric motor can be controlled by adjusting the voltage, current, or frequency of the electrical input.

Types of Electric Motors

Electric motors come in various types, each suited to specific applications and operating conditions. Common types of electric motors include AC (alternating current) motors such as induction motors and synchronous motors, as well as DC (direct current) motors such as brushed DC motors and brushless DC motors. Each type offers unique advantages in terms of efficiency, speed control, size, and cost, allowing for versatile use across different industries and applications.

AC Induction Motors

AC induction motors are the most commonly used type of electric motor, powering a wide range of industrial, commercial, and residential equipment. These motors rely on electromagnetic induction to produce rotational motion, with the rotating magnetic field generated by the stator inducing currents in the rotor. AC induction motors are robust, reliable, and cost-effective, making them ideal for applications requiring continuous operation and variable speed control.

Synchronous Motors

Synchronous motors are another type of AC motor that operates at a constant speed proportional to the frequency of the applied AC voltage. Unlike induction motors, synchronous motors require external means to initiate rotation, such as a starting mechanism or synchronous converter. Synchronous motors are widely used in applications where precise speed control, high efficiency, and synchronous operation with power grids are required, such as in industrial drives and power generation.

DC Motors

DC motors convert direct current electrical energy into mechanical energy through the interaction of magnetic fields. Brushed DC motors utilize brushes and a commutator to switch the direction of current flow in the rotor windings, resulting in continuous rotation. Brushless DC motors, on the other hand, use electronic controllers to drive the motor’s stator windings, eliminating the need for brushes and commutators. DC motors offer advantages such as high starting torque, precise speed control, and compact size, making them suitable for applications such as robotics, electric vehicles, and precision machinery.

Applications of Electric Motors

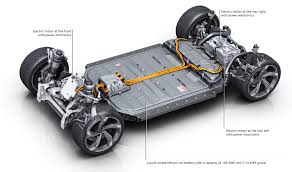

Electric motors find applications in a wide range of industries and sectors, powering devices and machinery essential for daily life and economic activity. In the automotive industry, electric motors drive electric vehicles, hybrid vehicles, and auxiliary systems such as power steering and HVAC (heating, ventilation, and air conditioning). In manufacturing and processing, electric motors operate pumps, compressors, conveyors, and machine tools, facilitating production processes and material handling. In residential and commercial buildings, electric motors drive HVAC systems, elevators, escalators, and appliances such as refrigerators, washing machines, and fans.

Efficiency and Energy Savings

Efficiency is a critical consideration in electric motor design and operation, as it directly impacts energy consumption and operating costs. High-efficiency electric motors, such as those meeting IE3 or IE4 efficiency standards, minimize energy losses and maximize performance, reducing electricity consumption and environmental impact. Variable speed drives (VSDs) and soft starters allow for precise control of motor speed and torque, further optimizing energy usage and enhancing system efficiency.

Maintenance and Service

Proper maintenance is essential for maximizing the lifespan and performance of electric motors. Regular inspection, lubrication, and cleaning help prevent issues such as bearing wear, overheating, and electrical faults. Monitoring motor operating conditions, such as temperature and vibration, can provide early warning signs of potential problems, allowing for timely intervention and preventive maintenance. In addition, scheduling periodic motor testing and alignment checks can help identify and address issues before they escalate into costly failures.

Troubleshooting Common Issues

Electric motors may experience various issues over time, ranging from mechanical problems such as bearing failure and misalignment to electrical issues such as insulation breakdown and winding faults. Common symptoms of motor problems include abnormal noise, excessive vibration, overheating, and reduced performance. Diagnosing and troubleshooting these issues require a systematic approach, including visual inspection, testing of electrical components, and analysis of motor operating conditions. Consulting with experienced technicians or engineers may be necessary to identify and address complex motor issues effectively.

Safety Considerations

Safety is paramount when working with electric motors, as they can pose hazards such as electrical shock, burns, and mechanical injury. Proper training, personal protective equipment (PPE), and adherence to safety procedures are essential when installing, operating, or servicing electric motors. Disconnecting power sources, locking out equipment, and following isolation procedures help prevent accidental energization and ensure the safety of personnel working on or near motor systems.

Environmental Impact

Electric motors play a significant role in energy consumption and environmental sustainability, as they account for a considerable portion of global electricity usage. Improving motor efficiency and implementing energy-saving measures can reduce greenhouse gas emissions and mitigate environmental impact. Recycling and proper disposal of end-of-life motors help recover valuable materials and minimize waste, contributing to a circular economy and sustainable resource management.

Future Trends and Innovations

The future of electric motors is marked by ongoing innovation and technological advancements aimed at improving performance, efficiency, and sustainability. Emerging trends such as the electrification of transportation, the integration of smart motor technologies, and the development of high-efficiency materials and design techniques are driving progress in the electric motor industry. As demand for energy-efficient and environmentally friendly solutions grows, electric motors are poised to play a central role in shaping a more sustainable future.

FAQs (Frequently Asked Questions)

What is the difference between AC and DC motors?

AC motors operate on alternating current, while DC motors operate on direct current. AC motors, such as induction and synchronous motors, are commonly used for applications requiring continuous operation and variable speed control. DC motors, including brushed and brushless types, offer advantages such as high starting torque, precise speed control, and compact size, making them suitable for applications such as robotics and electric vehicles.

How do I choose the right electric motor for my application?

Choosing the right electric motor depends on factors such as the specific application requirements, operating conditions, space limitations, and budget constraints. Considerations such as motor type, size,

speed, torque, efficiency, and environmental factors play a crucial role in selecting the most suitable motor for your needs. Consulting with motor manufacturers or engineers can help identify the best motor solution for your application.

What are some common maintenance tasks for electric motors?

Common maintenance tasks for electric motors include regular inspection, lubrication, and cleaning to prevent issues such as bearing wear, overheating, and electrical faults. Monitoring motor operating conditions, such as temperature and vibration, can provide early warning signs of potential problems, allowing for timely intervention and preventive maintenance. Periodic testing, alignment checks, and insulation resistance testing are also recommended to ensure optimal motor performance and longevity.

How can I improve the energy efficiency of electric motors?

Improving the energy efficiency of electric motors involves selecting high-efficiency motor models, optimizing motor sizing and speed control, and implementing energy-saving measures such as variable speed drives (VSDs) and soft starters. Proper maintenance, including regular inspection, lubrication, and cleaning, helps minimize energy losses and maximize motor performance. Additionally, upgrading to energy-efficient motor systems and implementing energy management strategies can further reduce electricity consumption and operating costs.

What are some common signs of motor problems?

Common signs of motor problems include abnormal noise, excessive vibration, overheating, and reduced performance. These symptoms may indicate issues such as bearing wear, misalignment, electrical faults, or mechanical defects. Visual inspection, testing of electrical components, and analysis of motor operating conditions can help diagnose motor problems and determine the appropriate course of action for troubleshooting and repair.

How can I ensure the safety of personnel when working with electric motors?

Ensuring the safety of personnel when working with electric motors involves following established safety procedures, using appropriate personal protective equipment (PPE), and adhering to electrical safety standards and regulations. Disconnecting power sources, locking out equipment, and following isolation procedures help prevent accidental energization and ensure the safety of individuals working on or near motor systems. Proper training and supervision of personnel are essential to promote a culture of safety in motor-related activities.

What are the environmental considerations associated with electric motors?

Electric motors contribute to energy consumption and environmental impact, as they account for a significant portion of global electricity usage. Improving motor efficiency and implementing energy-saving measures can reduce greenhouse gas emissions and mitigate environmental impact. Recycling and proper disposal of end-of-life motors help recover valuable materials and minimize waste, contributing to a circular economy and sustainable resource management.

Conclusion:

Electric motors are indispensable devices that power a wide range of applications across industries and sectors. Understanding the principles, types, applications, and maintenance of electric motors is essential for maximizing their performance, efficiency, and longevity. By selecting the right motor for the application, implementing energy-saving measures, and adhering to safety and environmental considerations, users can ensure reliable operation and contribute to a sustainable future powered by electric motors.