Laser engraving is a technique that enables the creation of detailed designs on a range of materials. It has diverse applications, from personalized gifts to industrial purposes.

The process of laser engraving, supported materials, advantages, and constraints will be discussed. Additionally, guidance on initiating laser engraving endeavors will be provided.

The creative applications of laser engraving will be explored, accompanied by suggestions for crafting personalized laser engraving art. This journey aims to inspire creativity through the art of laser engraving.

What is Laser Engraving?

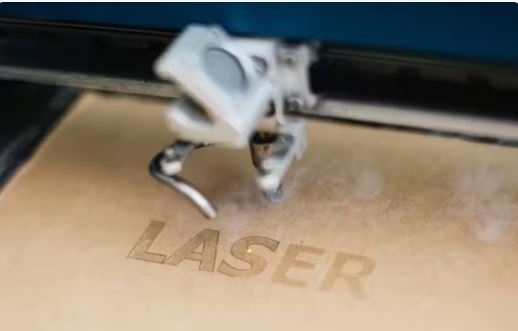

Laser engraving is a process that involves using laser technology to create detailed designs on different materials. This artistic form combines innovation, precision, and craftsmanship to produce unique patterns that showcase the artist’s creativity and skill.

The combination of artistry and technology in laser engraving enables highly customizable designs with precise details and exceptional accuracy. Artists begin by translating their vision into digital designs, which are then etched onto surfaces like wood, metal, glass, and acrylic. Laser engraving techniques have advanced to include 3D engraving, grayscale engraving, and even color transfers, expanding the possibilities of this contemporary art form.

How Does Laser Engraving Work?

Laser engraving is a process that involves using a focused laser beam to remove material and create detailed designs on various surfaces. This method necessitates specialized tools and equipment, as well as a thorough understanding of the materials being engraved.

The precision of the laser beam plays a crucial role in determining the exact depth and complexity of the design, which is vital for achieving the desired artistic outcome. Different materials react uniquely to the laser engraving process; for example, metals may produce a polished effect, whereas wood can result in a burnt appearance with contrasting tones.

Proficiency in laser engraving requires a combination of technical skills to operate the machinery proficiently and artistic vision to conceptualize and execute visually appealing designs.

What Materials Can Be Laser Engraved?

A variety of materials lend themselves well to laser engraving, such as wood, acrylic, leather, metal, and glass. Each material possesses distinct characteristics that enable the creation of personalized and customized designs with meticulous precision.

For example, wood imparts a cozy and natural appearance, making it a popular choice for those aiming for a rustic or organic aesthetic. Acrylic’s transparency can bring a modern twist, particularly when paired with backlighting to produce a striking effect. Leather projects a classic charm, with its ability to develop a lovely patina over time. Metal provides precision and durability in engraving, suitable for industrial or high-end applications. Glass delivers a sleek and sophisticated finish, perfect for crafting intricate designs that interact with light reflections.

What Are the Benefits of Laser Engraving?

Laser engraving has various advantages, such as extensive customization options, precise detailing, and the capability to realize artistic visions with exceptional craftsmanship.

The extensive customization offered by laser engraving allows for limitless opportunities in producing distinct and personalized pieces. Artists excel in this field as they can materialize their creative ideas into physical art with the utmost accuracy and complexity.

The meticulous craftsmanship attained through laser engraving establishes a superior benchmark in personalized creations, distinguishing them from conventional techniques. The capacity to engrave intricate designs on different materials introduces a realm of possibilities for crafting memorable and unique items.

What Are the Limitations of Laser Engraving?

Laser engraving is a powerful technique but has limitations when it comes to achieving intricate details and artistic expressions that may be more achievable through traditional methods.

This limitation is particularly noticeable in areas requiring fine and intricate work. Traditional methods like hand engraving or hand carving offer a level of precision and attention to detail that can be difficult to achieve with laser engraving.

The human touch, with its capability to adapt and make real-time adjustments, provides a unique advantage in creating complex designs or capturing nuanced artistic expressions. Technological constraints in laser engraving can sometimes limit the depth and intricacy of engravings, prompting artists to find creative solutions to work within these constraints and bring their artistic visions to fruition.

How to Get Started with Laser Engraving?

To begin a laser engraving journey, one must start by acquiring the necessary equipment, understanding the software used for design, and implementing essential safety precautions to ensure a smooth engraving process. Start by selecting a suitable laser engraving machine that matches project requirements, whether it’s a desktop model for smaller designs or a larger unit for more extensive work.

Next, familiarize oneself with design software such as CorelDRAW or Adobe Illustrator, allowing for the creation and customization of engraving patterns. It’s crucial to prioritize safety by wearing protective goggles, gloves, and ensuring proper ventilation in the workspace to prevent exposure to fumes.

Mastering basic engraving techniques such as adjusting laser speed, power, and focal length will build a strong foundation for future engraving endeavors.

What Equipment Do You Need?

Necessary equipment for laser engraving includes a laser engraving machine, appropriate safety gear, design software, and various tools for material preparation and finishing touches.

The laser engraving machine is the primary equipment used in the engraving process, emitting a focused beam of light to create detailed designs on different materials. Safety gear like protective goggles and gloves is vital to protect against potential laser hazards.

Design software is essential for designing and customizing patterns before engraving. Tools such as masking tape, brushes, and cleaning materials help in preparing the material surface and providing final touches to the engraved piece for a refined result.

What Software is Used for Laser Engraving?

Common software used for laser engraving includes Adobe Illustrator, CorelDRAW, and AutoCAD, among other options. These design programs provide artists with the tools to create intricate designs and patterns for laser engraving.

Artists depend on these versatile software applications to express their creativity and bring their ideas to fruition through laser-engraved artworks. Adobe Illustrator is recognized for its user-friendly interface and comprehensive set of tools, enabling artists to manipulate vector graphics easily and create precise designs. CorelDRAW excels in handling complex illustrations and text, offering advanced features for layout and typography. AutoCAD, known for its 3D modeling capabilities, is well-suited for artists seeking to incorporate depth and dimension into their laser-engraved creations. Together, these software tools enable artists to explore new possibilities in design and innovation.

What Are the Safety Precautions for Laser Engraving?

Safety is crucial in laser engraving, with measures such as wearing protective gear, ensuring proper ventilation, and understanding machine settings being necessary to maintain a secure working environment.

Creating a safe workspace is not just about preventing accidents but also plays a vital role in achieving high-quality engraving results. When using a laser engraving machine, it is important to have a clean and organized workspace that is free from clutter, which could impede the engraving process.

Precise calibration of the machine settings is essential to ensure accurate and consistent engravings. Attention to detail and craftsmanship are required to achieve intricate designs without compromising safety. By combining precision with adherence to safety protocols, engravers can produce stunning results while prioritizing their well-being.

What Are Some Creative Uses of Laser Engraving?

Laser engraving has a wide range of creative applications, such as creating personalized gifts, customizing home decor, producing promotional items, and meeting industrial needs.

Both individuals and businesses are attracted to the versatility of laser engraving, recognizing how it combines artistry and functionality. This tool allows artists to produce intricate designs with precision and detail, turning everyday objects into unique works of art. In industrial settings, laser engraving is crucial for marking and labeling products for branding and traceability. The capability to engrave on various materials, including wood, glass, metal, and plastic, further expands the possibilities of what can be accomplished using this advanced technology.

1. Personalized Gifts

The process of laser engraving allows for the creation of personalized gifts that feature unique designs and customization, enabling individuals to convey their feelings through intricately crafted items.

The precision of laser engraving technology enables the creation of detailed designs with exceptional clarity, capturing even the smallest nuances of the artwork. Whether it’s a personalized wooden photo frame or an engraved metal bookmark, the level of customization achievable through laser engraving is unmatched. These personalized gifts carry sentimental value as they are tailored to reflect the recipient’s personality and the relationship shared with the gift-giver. The impact of laser engraving in enhancing the sentiment and individuality of such gifts is significant.

2. Customized Home Decor

Laser engraving is a process that allows for the customization of home decor items. It involves incorporating design elements, craftsmanship, and artistic vision to create unique pieces that enhance the aesthetic appeal of living spaces.

Artisans utilize the precision of laser technology to add individuality and charm to everyday objects such as wooden signs, coasters, and picture frames. By combining innovative design concepts with skilled craftsmanship, these artists turn blank canvases into personalized masterpieces that reflect the personality and style of the homeowner. The artistry is evident in the intricate detailing and meticulous planning that are put into each piece, showcasing a commitment to quality and creativity that is evident in the final product.

3. Promotional Items

Laser engraving is commonly used to produce promotional items with distinctive designs, meticulous workmanship, and the integration of advanced technology to boost brand visibility and attractiveness.

These elaborate designs are achievable thanks to the precision of laser beams, which can inscribe intricate patterns or logos onto various materials like metal, wood, glass, and acrylic. The skilled work involved in laser engraving ensures refined finishes that convey professionalism and sophistication, enhancing the appeal of the promotional items to recipients.

Progress in laser engraving technology has introduced customization possibilities that enable brands to develop truly unique merchandise, distinguishing themselves from competitors in the market.

4. Industrial Applications

The industrial applications of laser engraving are wide-ranging, spanning various sectors such as manufacturing and aerospace. This technique is valued for its precision, craftsmanship, and customization capabilities, which cater to a variety of industrial needs.

Laser engraving plays a crucial role in industrial processes, from creating intricate markings on aerospace components to branding manufactured goods. The precision and permanence of laser markings on a diverse range of materials like metals, plastics, and ceramics make lasers essential tools for industries aiming for efficient production and robust quality control practices.

By integrating laser engraving technology, businesses can achieve high levels of accuracy, consistency, and efficiency in their operations, leading to increased competitiveness and customer satisfaction.

How to Create Laser Engraving Art?

The process of creating laser engraving art involves a series of steps, which include:

- Designing the artwork

- Preparing the material

- Setting up the engraving machine

- Executing the engraving process with precision and skill

Before beginning the design phase, it is important to determine the type of material to be engraved as different materials may require different settings on the engraving machine. Once the material is chosen, careful attention to detail in the design phase is necessary to ensure a flawless final product. Following finalization of the design, thorough preparation of the material for engraving by proper securing is essential for consistent results. Accurate configuration of the engraving machine based on the material and design specifications significantly influences the outcome. Running the engraving process with precision and care is crucial for bringing the artwork to life with clear detailing and precision.

1. Designing the Artwork

The process of designing artwork for laser engraving involves engaging in the creative process, seeking inspiration from diverse sources, and transforming artistic concepts into digitally rendered designs for engraving. Artists undertake a creative exploration where they consider a range of ideas, themes, and concepts before refining a distinctive design. By striking a balance between imagination and technical proficiency, they realize their vision on the digital platform, ensuring that each element is carefully crafted for optimal engraving. Designing for laser engraving necessitates a thorough comprehension of the medium’s capabilities, allowing artists to experiment with textures, shading, and intricate details that will effectively transfer onto various surfaces.

2. Preparing the Material

The process of material preparation in laser engraving includes selecting the appropriate substrate, ensuring the surface is suitable for engraving, and applying craftsmanship techniques with precision to prepare the material for the engraving process.

The initial important step in preparing materials for laser engraving is carefully choosing the substrate. Different substrates, like wood, acrylic, metal, or glass, require specific considerations based on their properties and intended use.

Once the substrate is selected, the surface must be treated meticulously to ensure optimal results during the engraving process. Craftsmanship is crucial in this stage, as attention to detail is necessary for achieving high-quality engraved designs. Precision techniques, such as adjusting power and speed settings, are then used to optimize the material’s suitability for engraving.

3. Setting Up the Laser Engraving Machine

The process of setting up the laser engraving machine includes configuring the laser parameters, adjusting focus settings, and aligning the material accurately to achieve precise engraving results with detailed designs. Calibrating the laser parameters involves setting the power, speed, and frequency settings to match the material being engraved. Focus adjustments are necessary for achieving sharp and clear engravings, ensuring the laser beam is accurately focused on the surface. Proper alignment of the material is crucial to position the design correctly for consistent engraving across the entire surface. These detailed setup procedures are essential in determining the efficiency and quality of the engraving process, ultimately influencing the final output.

4. Running the Engraving Process

The engraving process involves overseeing the laser operation, monitoring design progression, and infusing creative ideas and artistic style with precision to bring the envisioned artwork to life through laser engraving.

During the operational phase, it is crucial to maintain a keen eye on the laser’s movement and power levels to ensure the accuracy and depth of the engraving. Design monitoring techniques play a key role in adjusting settings and modifying the artwork in real-time for optimal results. Integrating creative ideas involves experimenting with different patterns, textures, and fonts to enhance the overall visual impact. Attention to detail is paramount, as even minor adjustments can significantly impact the final product’s aesthetic appeal and quality.

Frequently Asked Questions

What is laser engraving?

Laser engraving is a process that uses a laser beam to etch designs or patterns onto various materials, such as wood, metal, glass, and acrylic. It is a precise and efficient way to create detailed and intricate designs.

What is unique about laser engraving artistry?

Laser engraving artistry combines the use of technology and creativity to produce one-of-a-kind pieces. The precision of laser engraving allows for intricate and detailed designs that can’t be achieved through traditional methods.

Can any design be laser engraved?

Yes, laser engraving can reproduce almost any design, including logos, text, and even photographs. However, some designs may require alterations or simplification to achieve the best results.

What materials can be used for laser engraving?

Common materials for laser engraving include wood, acrylic, glass, leather, and metal. However, there are many other materials that can be engraved, such as stone, fabric, and paper.

Is laser engraving permanent?

Yes, laser engraving creates a permanent mark on the material. The laser actually burns or vaporizes the surface of the material, creating a deep and long-lasting engraving.

Can laser engravings be customized?

Absolutely! One of the greatest advantages of laser engraving artistry is the ability to customize designs. You can choose the material, size, and design to create a truly unique and personalized piece.