Metal stepping is a basic cycle in the assembling business, assuming a urgent part in making a wide cluster of items, from car parts to electronic parts. The accuracy and dependability of metal stepping administrations are vital for guaranteeing the nature of the final results. This is where Quality Affirmation (QA) moves toward, filling in as the watchman of greatness in the metal stepping process.

Understanding Metal Stamping

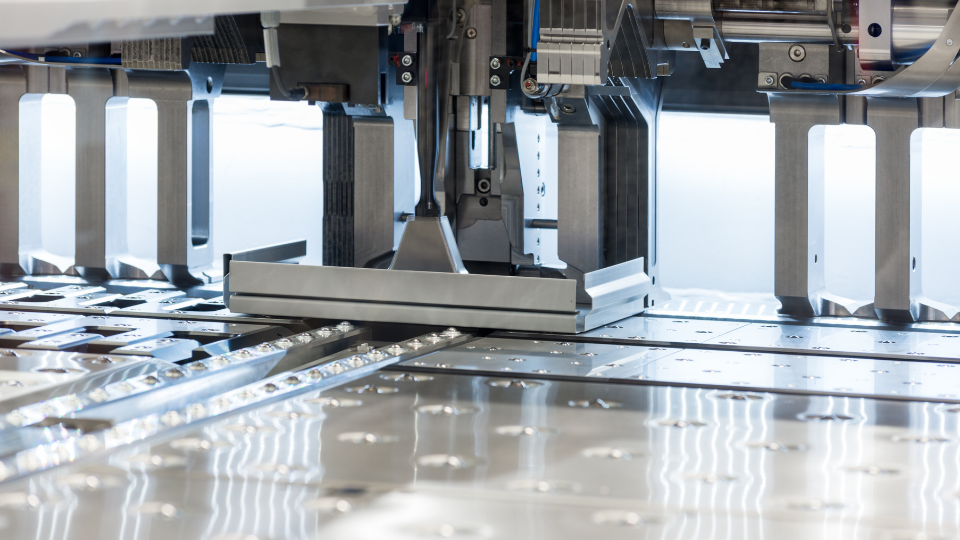

Metal stepping includes the forming and slicing of metal sheets to make different parts and parts. The interaction depends on specific apparatus, including stepping presses and bites the dust, to change crude metal materials into wanted shapes and sizes. It is a practical and proficient strategy for large scale manufacturing, making it basic to various ventures.

The Importance of Precision in Metal Stamping

Accuracy is fundamental in metal stepping, as even the smallest deviation from plan determinations can prompt faulty metal stamping service and compromised safety. Whether it’s the auto area, hardware, or aviation, producers rely upon the precision of metal stepping cycles to convey parts that fulfill rigid quality guidelines.

Quality Assurance: The Guardian of Precision

In the domain of metal stepping administrations, Quality Confirmation fills in as the forefront safeguard against deformities and flaws. QA experts are entrusted with executing thorough investigation processes all through each phase of metal stepping, from the underlying plan stage to the end result examination.

Design Phase: Setting the Foundation for Quality

The primary line of guard starts with a fastidious survey of the plan details. QA specialists team up with configuration designers to guarantee that everything about precisely converted into the metal stepping process. This incorporates surveying resistances, material necessities, and mathematical contemplations.

By getting possible issues at the plan stage, QA keeps exorbitant blunders from engendering all through the assembling system. Any disparities or ambiguities are tended to immediately, establishing the groundwork for a consistent and exact metal stepping activity.

Material Inspection: Quality Starts with Raw Materials

Quality Affirmation stretches out its compass to the unrefined components utilized in metal stepping. The organization, thickness, and generally nature of the metal sheets are investigated to guarantee they fulfill the predefined guidelines. Any deviation from the endorsed material properties could bring about a cascading type of influence of issues during the stepping system.

Ordinary material testing and clump assessments are led to recognize and correct any varieties. This proactive methodology guarantees that main materials of the greatest quality are utilized, adding to the general dependability of the stepped parts.

Stamping Process Oversight: Continuous Monitoring for Excellence

As the metal stepping machines show some major signs of life, QA experts keep careful focus on the whole cycle. Nonstop observing incorporates ongoing estimations, visual examinations, and occasional quality checks. This cautiousness distinguishes abnormalities, for example, device wear or machine breakdowns, before they compromise the trustworthiness of the stepped parts.

Trend setting innovations, for example, mechanized frameworks and sensors, help QA groups in gathering and examining information during the stepping system. This information driven approach upgrades the proficiency and exactness of value control measures, guaranteeing that each stepped part sticks to the predetermined principles.

Final Inspection: Sealing the Deal with Assurance

The perfection of the metal stepping process is set apart by a thorough last examination. This stage includes a careful assessment of each stepped part to check its layered precision, surface completion, and by and large quality. Any parts that miss the mark regarding the severe measures are hailed for additional examination or revise.

The last investigation not just fills in as the last line of safeguard against surrenders yet in addition gives important criticism to handle improvement. Persistent refinement of value control processes is fundamental for adjusting to developing assembling prerequisites and keeping an upper hand in the business.

Conclusion: Ensuring Excellence in Every Stamp

In the unique universe of metal stepping administrations, Quality Confirmation arises as the uncelebrated yet truly great individual, it are not compromised to guarantee that accuracy and dependability. From the commencement of plan to the last examination, QA experts assume a crucial part in maintaining the norms that characterize the outcome of metal stepping view processes. As ventures keep on requesting top notch stepped parts, the job of Value Confirmation stays key, stepping and fixing the way to greatness in assembling.